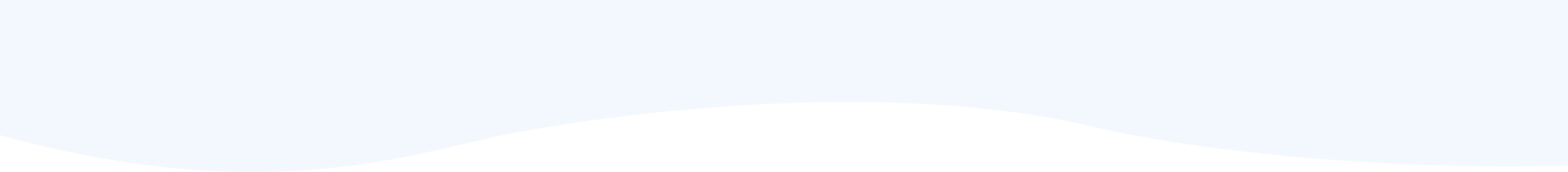

About ECT

At Zengary, our certified technicians use specialized eddy current testing equipment to provide a quick and accurate examination of:

-

Aircraft and engine components

-

Heat exchanger tubing

-

Other critical engineering components

Zengary’s eddy current inspection offers a cost-effective technique to inspect metals for surface cracks, pitting, wall loss and other discontinuities.

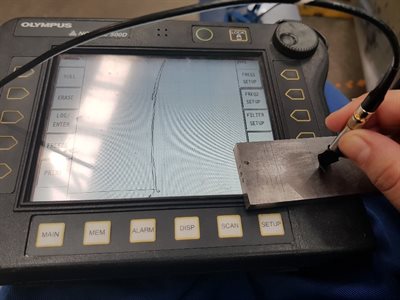

Eddy current inspection can be used to find the finest surface and near-surface flaws in any conductive material. Our highly trained eddy current specialists analyze results using advanced software to differentiate relevant and non-relevant indications.

Testing measure & testing inspection

- Crack detection

- Material thickness measurements

- Coating thickness measurements

-

Conductivity measurements for:

- Material identification

- Heat damage detection

- Case depth determination

- Heat treatment monitoring

- Aircraft structures, units and engines

- Boilers, heat exchangers, cast iron pipes, and pipelines using remote field testing

- Gears, blades, bolts, bolt holes, threading, shafts, flanges, nozzles

- Manufacturing and transportation equipment

- Automotive parts

Contact Zengary For Eddy Current Solutions

Contact us online to get in touch with a Zengary representative about our Eddy Current services