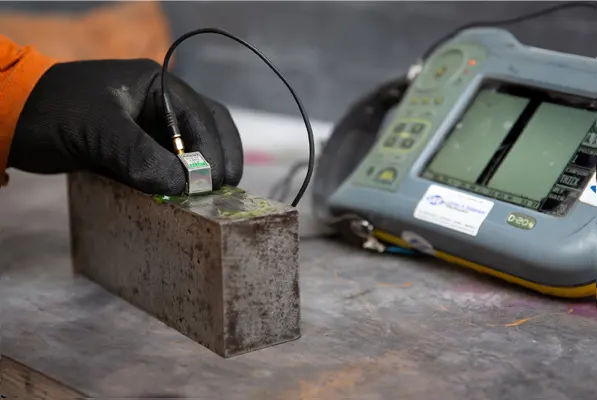

Our services include manual and automated mapping, and weld examinations for numerous applications including piping, tanks, vessels and processing plants.

Certified ISO 9712

Zengary’s UT team are certified ISO 9712, and provide quick, accurate ultrasonic testing results enabling you to make the right decision fast.

Zengary’s nondestructive testing reveals subsurface flaws without the safety hazards associated with radiography. Ultrasonic testing services range from manual thickness readings to large-scale automated corrosion mapping to phased array flaw detection. All ultrasonic inspection services are executed in compliance with industry codes and standards such as ASME, API and AWS.

Benefits include:

-

Great option to inspect surface and subsurface levels

-

Inspection provides both thickness measurement and flaw detection

-

Superior depth of penetration

-

Instant results

-

More safe and environmentally safe than radiography

-

Regulatory requirement

-

Only single-sided access is required to perform the test

The smartest access means up to 12m

We conduct ultrasonic at height using extendable 12m length poles.

-

Suppress the risks and reduce the procedures and the cost associated to work at heights.

-

A-Scan and B-Scan, VT up to 12m.

-

Relevant for low thickness / unknow roofs.

Contact Zengary For Ultrasonic Testing Solutions

Contact us online to get in touch with a Zengary representative about our ultrasonic testing services