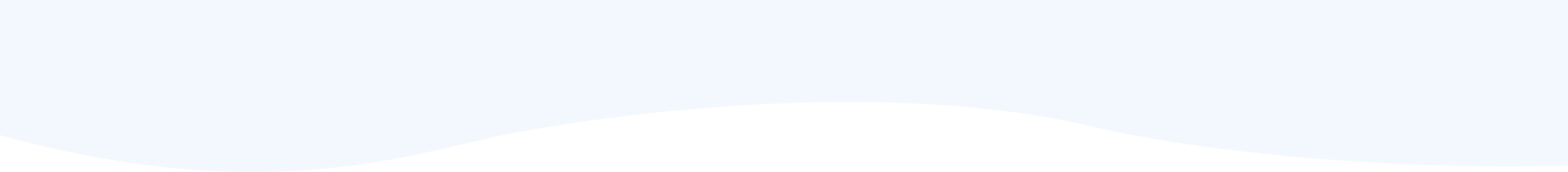

Portable XRF Spectrometers

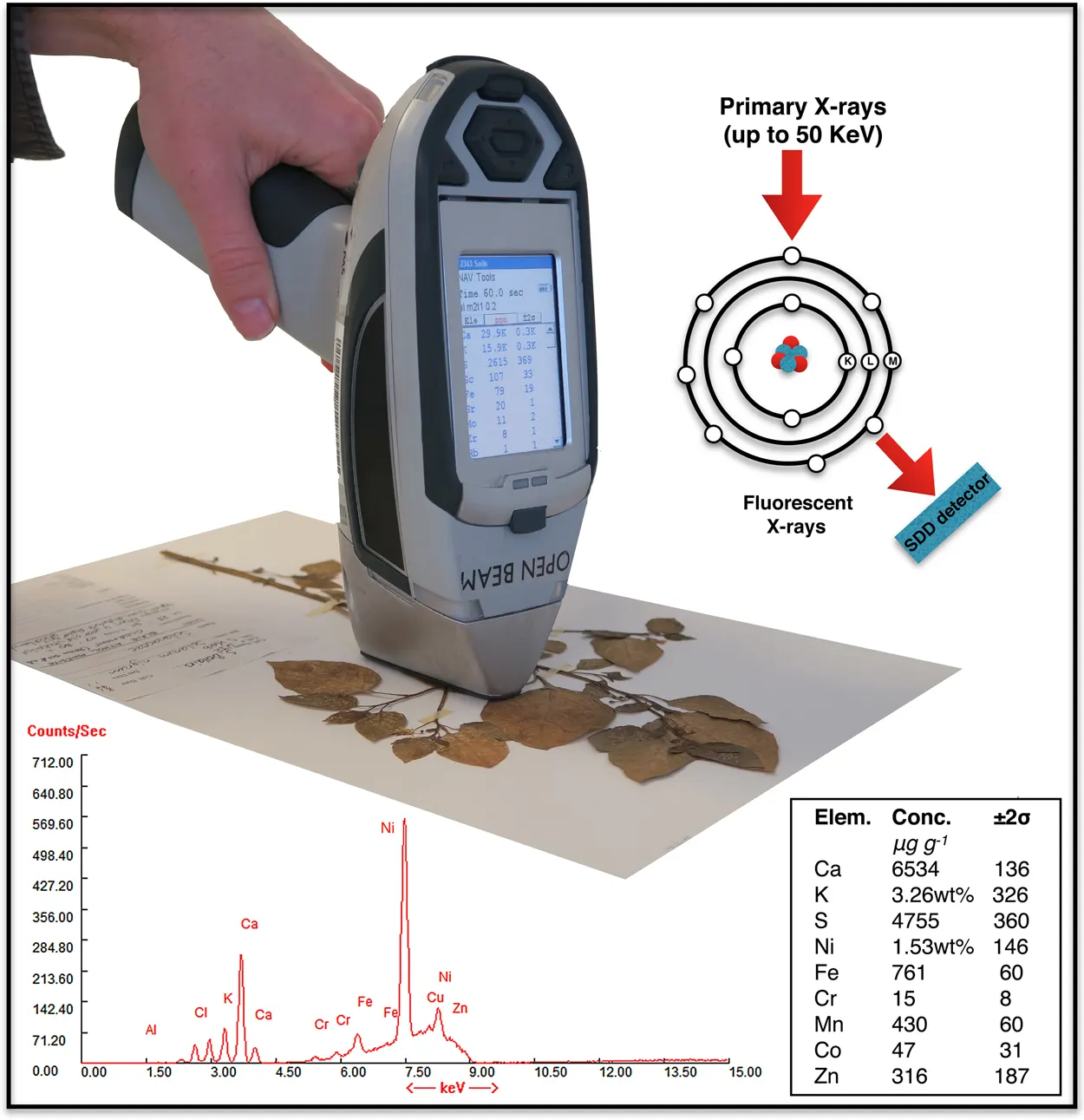

XRF (X-ray fluorescence) is an innovative, non-destructive technology for material analysis. It`s unique and almost universal, given you get a high-quality XRF gun (handheld XRF).

An X-ray gun sees sample contents by using an X-ray source to measure the secondary ways (fluorescent) the sample emits. Such an analysis is clear and fast.

Portable XRF Limitations

Both isotope and x-ray methods of XRF are semi-quantitative as there are various elements that avoid detection. These instruments cannot detect carbon, therefore alloy grades such as SS304 and 304L cannot be differentiated. Zengary’s reports the results as “closest match”, which indicates the alloy composition is consistent with the specified alloy material. The amount of specific elements detected are also reported for each material tested. Portable XRF should not be used on components in significant vibration service or where background electromagnetic fields are excessive.

PMI Services for Industries

Positive material identification (PMI) by x-ray fluorescence (XRF) is performed in every industry sector including:

- Offshore

- Pipeline

- Oil & Gas

- Structural

- Aerospace

- Mining

- Nuclear Power

- And more…

Contact Zengary For XRF Solutions

Contact us online to get in touch with a Zengary representative about our XRF services