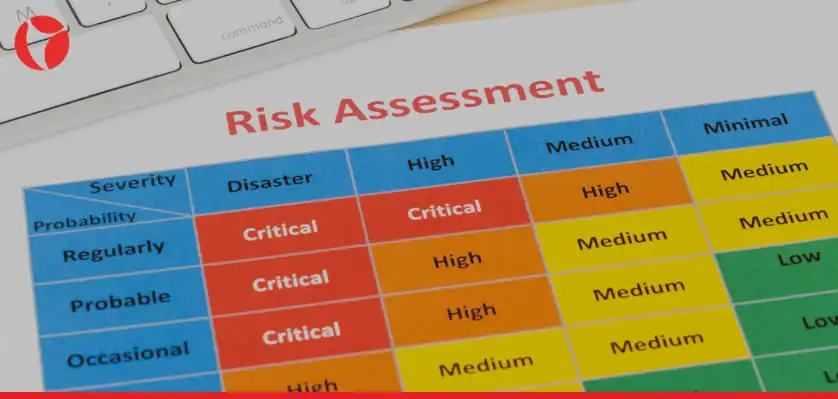

Zengary with industry certified and experienced API 580 individuals will conduct Risk-Based Inspection (RBI) analysis methodology and process that, as opposed to condition-based inspection, requires qualitative or quantitative assessment of the probability of failure (PoF) and the consequence of failure (CoF) associated with each equipment item, piping circuits included, in a particular process unit.

Why use consult Zengary to develop a RBI for you?

Zengary will avail its experienced and certified personnel per API 580 such as Risk Analysts, Inspection specialists RBI Team members to facilitate a successful implementation and reassessment of RBI.

RBI is used to identify and understand risk, risk drivers, and where equipment is in its lifecycle. RBI can indicate whether inspection is needed; however, this requires additional data that is extremely targeted to reduce the underlying uncertainties associated with the risks about the current and future predicted damage state of the equipment. RBI should not be used to recommend any inspection when it will not improve knowledge about the damage state. In those cases, where PoF is driving the risk, RBI should point to other mitigation options such as replacement, repair, or other actions that satisfy the risk criteria.

RBI can be used to prioritize inspection-related activities, usually by means of nondestructive testing (NDT), in order to reduce the uncertainties around the true damage state of the equipment and the dynamics leading to such. The resulting inspection plan may outline the type and scheduling of inspection for an asset. In addition to NDE, additional risk mitigation activities identified by an RBI assessment might include a change in material of construction, installation of corrosion resistant liners, operating condition changes, injection of corrosion inhibition chemicals, etc.

Consistency and repeatability of analysis are critical to producing an effective RBI program, as RBI is based on relative risks. Caution should be used when mixing RBI platforms (e.g., using a qualitative method to perform the initial screening and quantitative methods to conduct the final analysis). Complementary methodologies must be calibrated against one another to ensure valid cut sets are achieved.

Contact Zengary For Risk Based Inspection Solutions

Contact us online to get in touch with a Zengary representative about our Risk Based Inspection services